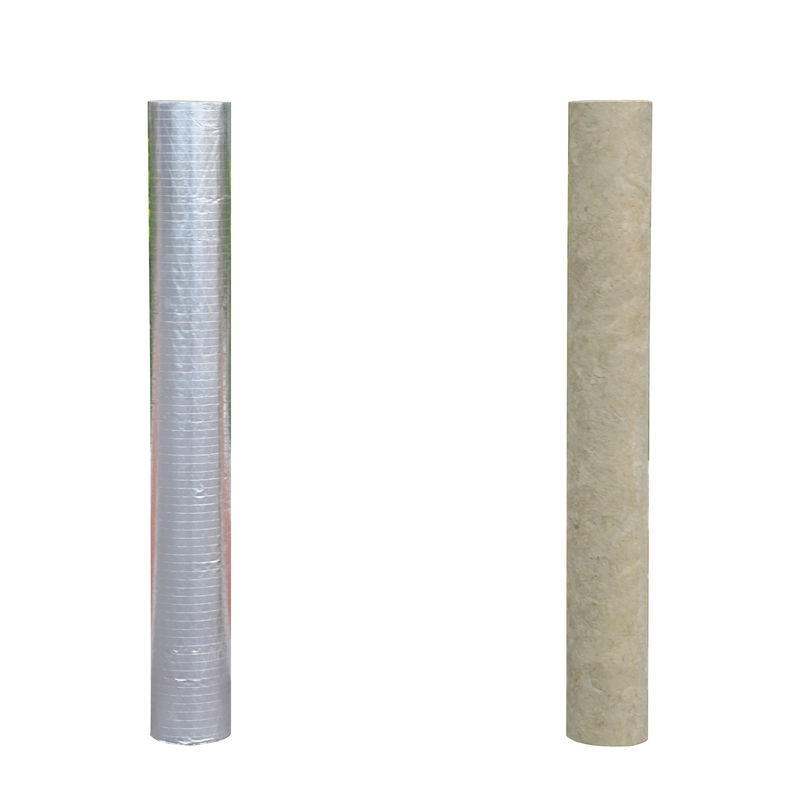

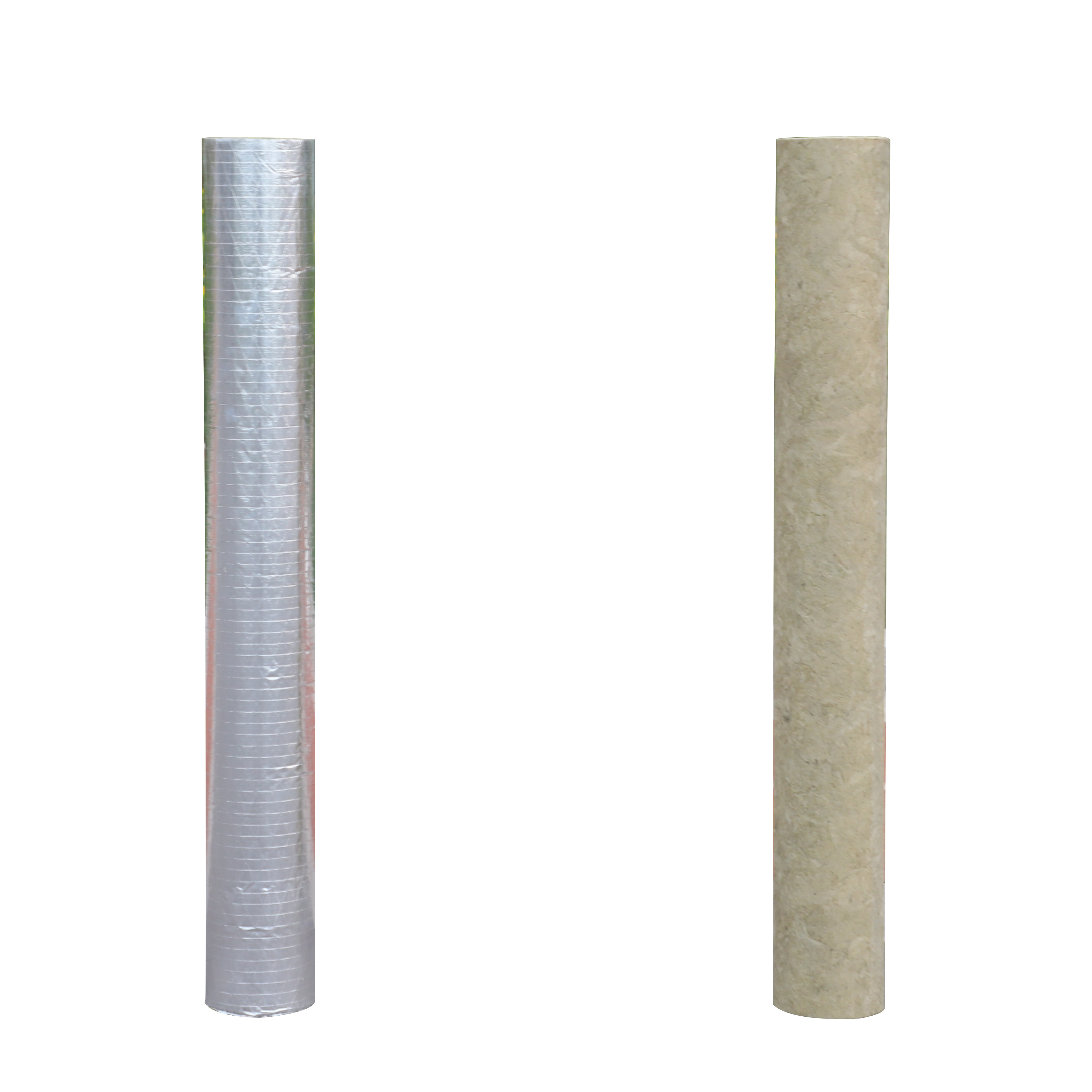

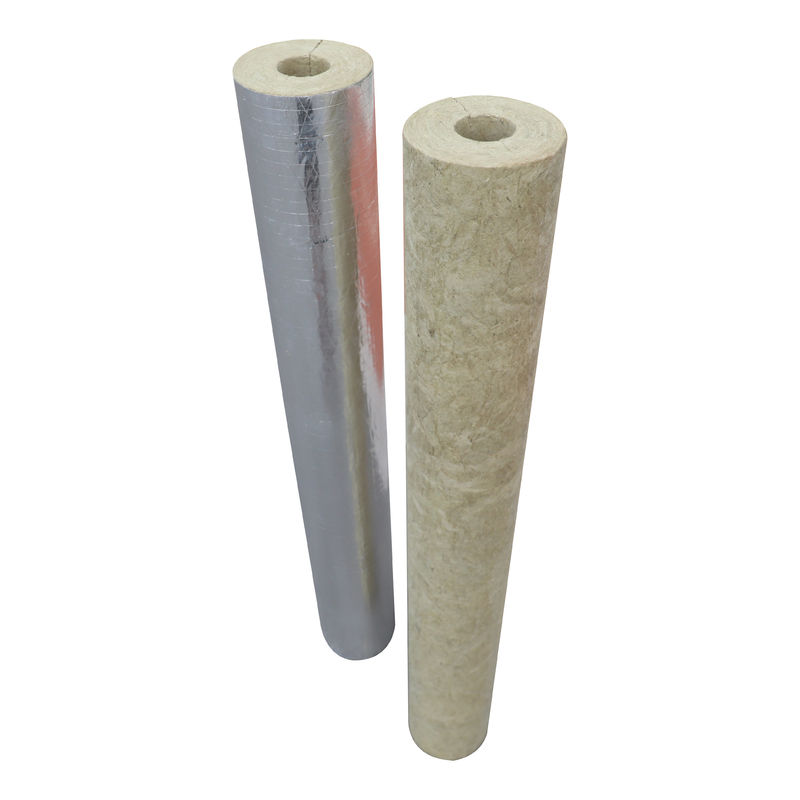

Высокотемпературные предварительно изолированные трубы каменная вата минеральная вата изоляция с алюминиевой фольгой для HVAC каналов Трубы водопроводные

Введение продуктаиз трубы из каменной шерсти с алюминиевой фольгой

ФАНРИНТруба из каменной шерсти изготавливается из природных пород, таких как базальт и известняк.°C, а расплавленная лава фибризируется спиннером.Неорганические волокна связывают друг с другом с помощью термоустойчивой смолы, чтобы сформировать конечный продукт, который разрезают на подходящие размеры для легкой обработки и установки.

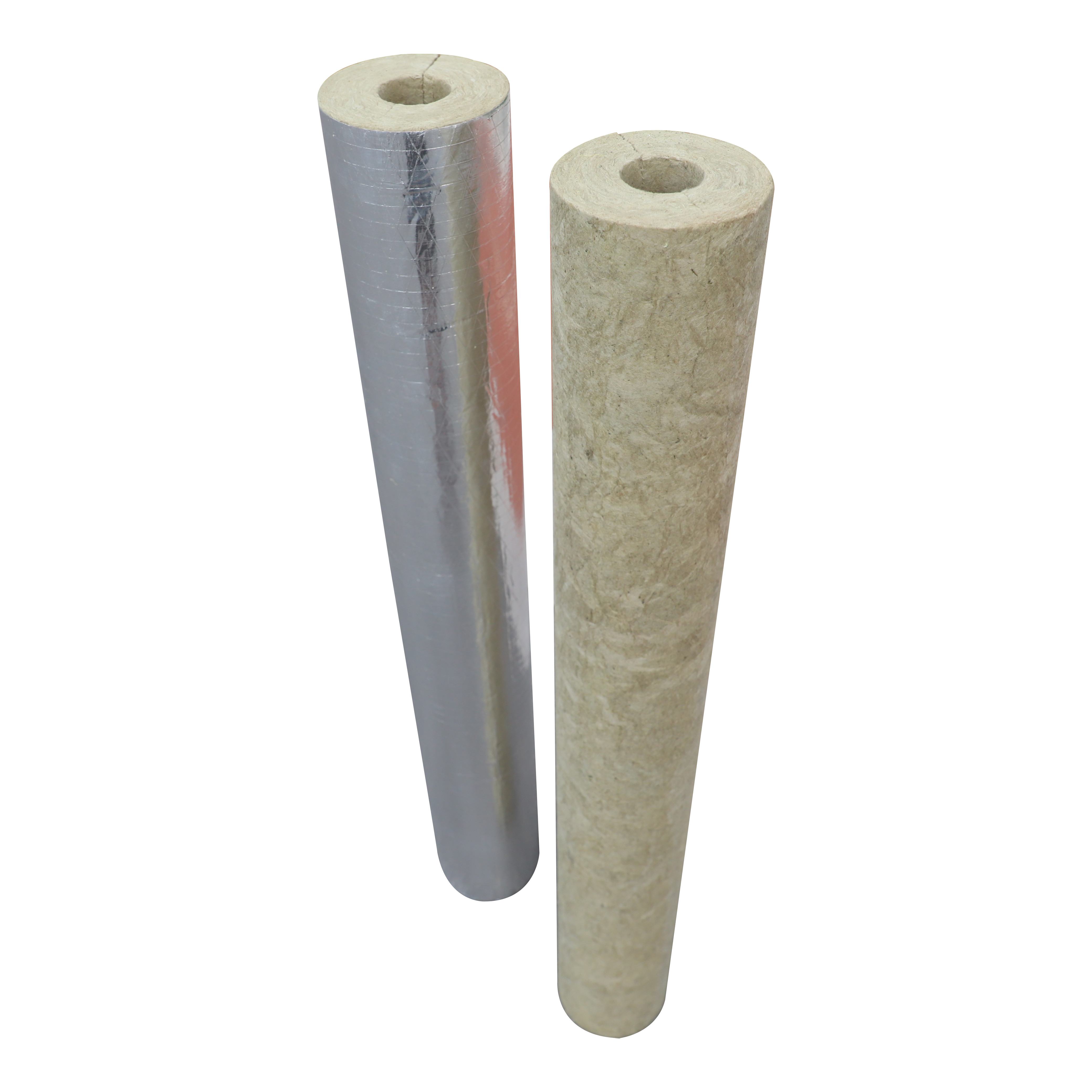

Подробная информация о производстветрубы из каменной шерстис алюминиевой фольгой

Параметр продукта трубы из каменной шерстис алюминиевой фольгой

|

Свойства

|

Спецификации

|

Стандарты

|

|

Толерантность к плотности

|

±15%

|

ГБ/Т 19686-2005

|

|

Огневая производительность

|

Не горючие

|

GB/T 5464-1999

|

|

Реакция на огонь класса А1

|

GB/T 8624-2006

|

|

Теплопроводность

(W/mK, при 70±5°C)

|

≤ 0.044

|

GB/T 10295

|

|

Диаметр волокна

|

7 ((+/-1) мм

|

ГБ/Т 5480. 4

|

|

Содержание снимка

(размер снимка)>0.25 мм)

|

≤12%

|

|

|

Эксцентричность оболочки трубы

|

≤ 5 мм

|

|

Размер продукции трубы из каменной шерстис алюминиевой фольгой

|

DIA

|

Толщина (мм)

|

|

дюйм

|

мм

|

25

|

30

|

40

|

50

|

60

|

70

|

80

|

90

|

100

|

120

|

150

|

|

1/2 ′′

|

22

|

●

|

●

|

|

●

|

|

|

|

|

|

|

|

|

3/4 ′′

|

27

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

|

|

|

|

|

1 ¢

|

34

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

|

|

|

|

|

1-1/4

|

43

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

|

|

|

1-1/2

|

48

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

|

|

|

2 ¢

|

60

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

|

|

|

2-1/2

|

76

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

|

|

|

3 ¢

|

89

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

|

|

|

3-1/2

|

108

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

|

|

|

4 ¢

|

114

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

|

|

5 ¢

|

140

|

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

|

6 ¢

|

169

|

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

|

8 ¢

|

219

|

|

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

|

10 ¢

|

273

|

|

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

|

12 ¢

|

325

|

|

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

|

14 ¢

|

356

|

|

|

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

|

15 ¢

|

381

|

|

|

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

|

16 ¢

|

406

|

|

|

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

|

18 ¢

|

456

|

|

|

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

|

19 ¢

|

483

|

|

|

|

|

|

●

|

●

|

●

|

●

|

●

|

●

|

|

20 ¢

|

508

|

|

|

|

|

|

●

|

●

|

●

|

●

|

●

|

●

|

|

22 ¢

|

558

|

|

|

|

|

|

|

●

|

●

|

●

|

●

|

●

|

|

24 ¢

|

610

|

|

|

|

|

|

|

●

|

●

|

●

|

●

|

●

|

Особенности продуктатрубы из каменной шерстис алюминиевой фольгой

1Отличная теплоизоляция.

Эффективно предотвращает потерю/прибыль тепла и заморозку труб при значительном сокращении потребления энергии.

2Высокая огнестойкость (класс A1)

- Выдерживает температуру свыше 1000°C, предотвращая распространение огня через трубопроводы.

3Эффективное снижение шума

- Поглощает шум потока жидкости и вибрации оборудования, идеально подходит для больниц и отелей.

4- Коррозионностойкий материал.

- Химически инертные свойства предотвращают коррозию металлических труб.

5.Экологически чистое производство

- Изготовлен из природного базальта и переработанной шлаки с возможностью переработки производственных отходов.

6.Интегрированный паровый барьер

-Алюминиевая фольга обеспечивает постоянную защиту от влаги для поддержания тепловых характеристик.

7.Сокращение выбросов углерода в жизненном цикле

Снижает выбросы углерода более чем на 30% на протяжении всего срока службы.

8Легкая установка и обслуживание

Гибкая конструкция адаптируется к различным конфигурациям труб с встроенным защитным облицованием.

Продуктовое применение голыхтрубы из каменной шерсти

Изоляция и огнестойкость крупных проектов, таких как электростанции, нефтяные склады и нефтехимические предприятия.

Производственная упаковка голых труб из каменной шерсти

Часто задаваемые вопросы

Q1: Как гарантировать качество продукции?

A1: Наша опытная команда QC будет проверять качество продукта в каждом процессе

Q2: Как упаковать экспортируемые товары?

A2: Пластиковые пакеты (стандартная экспортная упаковка).

Вопрос 3: каково ваше время выполнения заказа на один контейнер 40HC?

A3: Обычно 7-10 рабочих дней после заказа.

Вопрос 4: Каково ваше преимущество по сравнению с трубой из каменной шерсти?

А4:Специальный продукт со специальными характеристиками может быть изготовлен на заказ.

Q5: Что касается послепродажного обслуживания, как решить проблемы, возникшие у ваших зарубежных клиентов вовремя?

A5: Гарантия на наши продукты составляет один год. Если у наших продуктов или упаковки есть проблемы с качеством, мы заменим или компенсируем соответственно.

Ваше сообщение должно содержать от 20 до 3000 символов!

Ваше сообщение должно содержать от 20 до 3000 символов! Пожалуйста, проверьте свою электронную почту!

Пожалуйста, проверьте свою электронную почту!  Ваше сообщение должно содержать от 20 до 3000 символов!

Ваше сообщение должно содержать от 20 до 3000 символов! Пожалуйста, проверьте свою электронную почту!

Пожалуйста, проверьте свою электронную почту!